Compatible Vehicle Models

| Year

| Make

| Model

| Engine

|

|---|

| 1998-2001 | INFINITI | I30 | 3.0L V6 |

| 2002-2004 | INFINITI | I35 | 3.5L V6 |

| 1995-2000 | Nissan | Maxima | 3.0L V6 |

| 1995-2000 | Nissan | Maxima | 3.5L V6 |

| 2002-2003 | Nissan | Maxima | 3.0L V6 |

| 2002-2003 | Nissan | Maxima | 3.5L V6 |

| 2003-2007 | Nissan | Murano | 3.5L V6 |

| 2009 | Nissan | Murano | 3.5L V6 |

Why Remanufactured Alternators Deliver Reliability, Stability and High-Output?

Remanufactured alternators are meticulously designed and undergo a rigorous process to ensure reliability, durability, and high performance. This comprehensive process guarantees that each alternator exceeds OEM quality standards, making them a trusted option for vehicle owners. Each alternator undergoes the following

5-step remanufacturing process

:

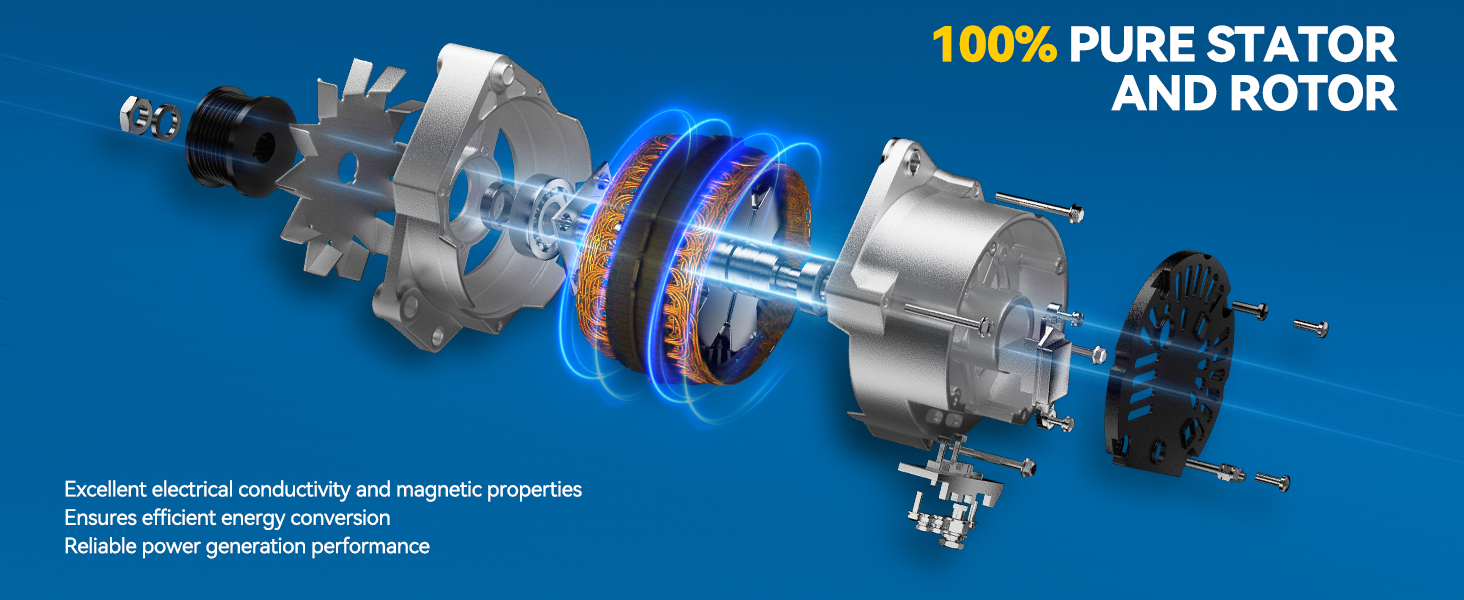

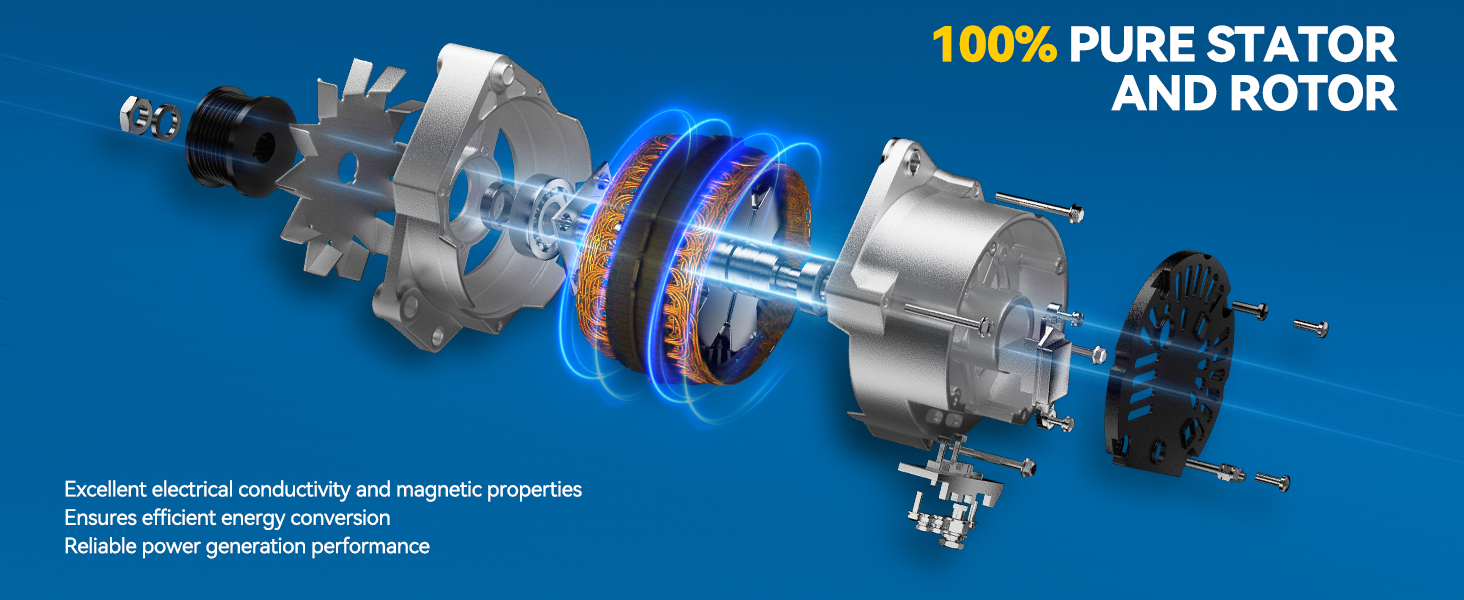

1. Initial Selection and Evaluation

:

Before the remanufacturing process begins, each alternator is carefully selected to ensure it is suitable for restoration. Only alternators that meet strict criteria, such as those with key components like the

rotor, stator, and voltage regulator

in good condition, are chosen for remanufacturing.

2. Disassembly and Inspection

:

After selection, the alternator is fully disassembled, and all components are meticulously inspected.

Bearings, slip rings

, and other critical parts are checked for wear, damage, or corrosion. Worn or non-functioning parts, such as

bearings and rectifiers

, are replaced with new or reconditioned components to ensure long-term reliability and performance.

3. Component Replacement and Reconditioning:

Critical high-wear parts, including the

rotor, bearings, slip rings, and voltage regulator

, are either reconditioned or replaced with high-quality new parts. The bearings are 100% tested to OEM specifications and repacked with premium lubricant, while the

voltage regulator

is tested to meet original standards. This step ensures that the alternator meets or exceeds the manufacturer's specifications, providing dependable performance.

4. Cleaning and Reassembly:

The remaining functional components, such as the

housing and stator

, are thoroughly cleaned to remove any dirt, corrosion, or carbon deposits. The

slip rings

are re-machined to minimize brush wear and abrasion. After cleaning, the alternator is reassembled by experienced technicians, following strict industry guidelines to ensure a precise fit and optimal operation.

5. Advanced Testing

Each remanufactured alternator undergoes comprehensive testing, including voltage output and load simulations. The

rotor, stator, rectifier, and voltage regulator

are tested for performance under load conditions to verify correct torque, electrical output, and overall performance. The stator and rotor are insulation tested to

600 volts

to ensure durability and reliability in real-world conditions.

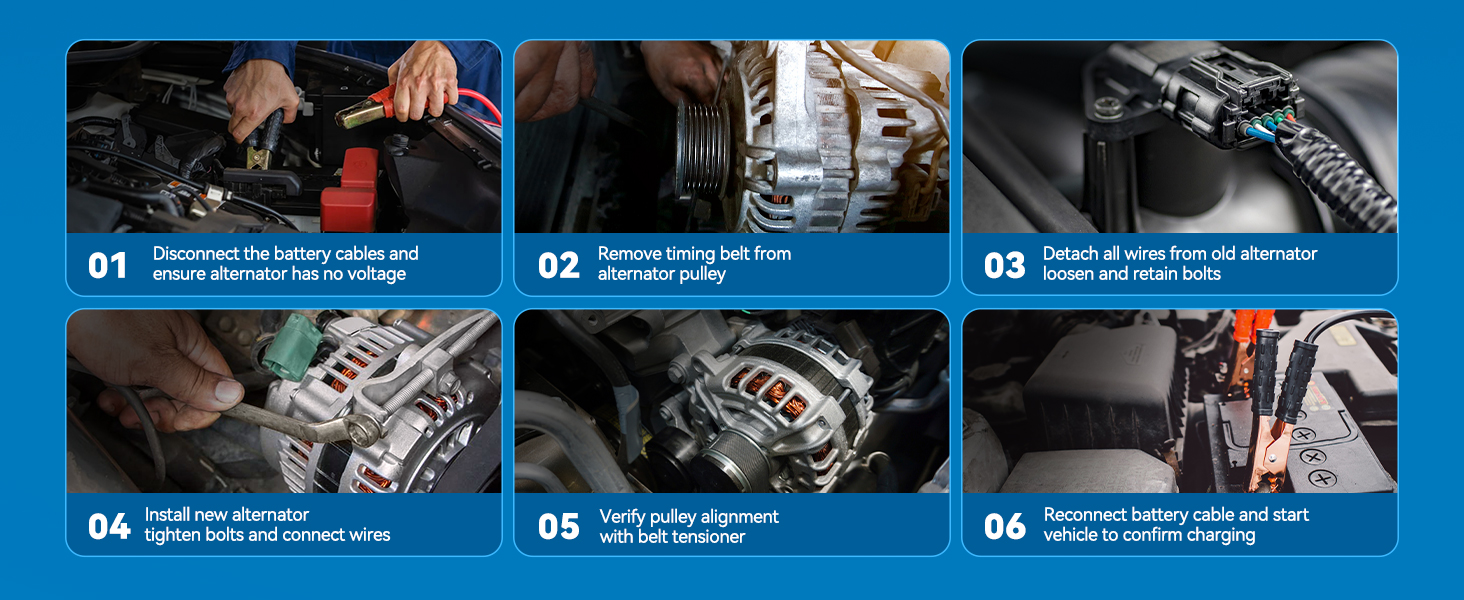

How to Install a Car Alternator ?

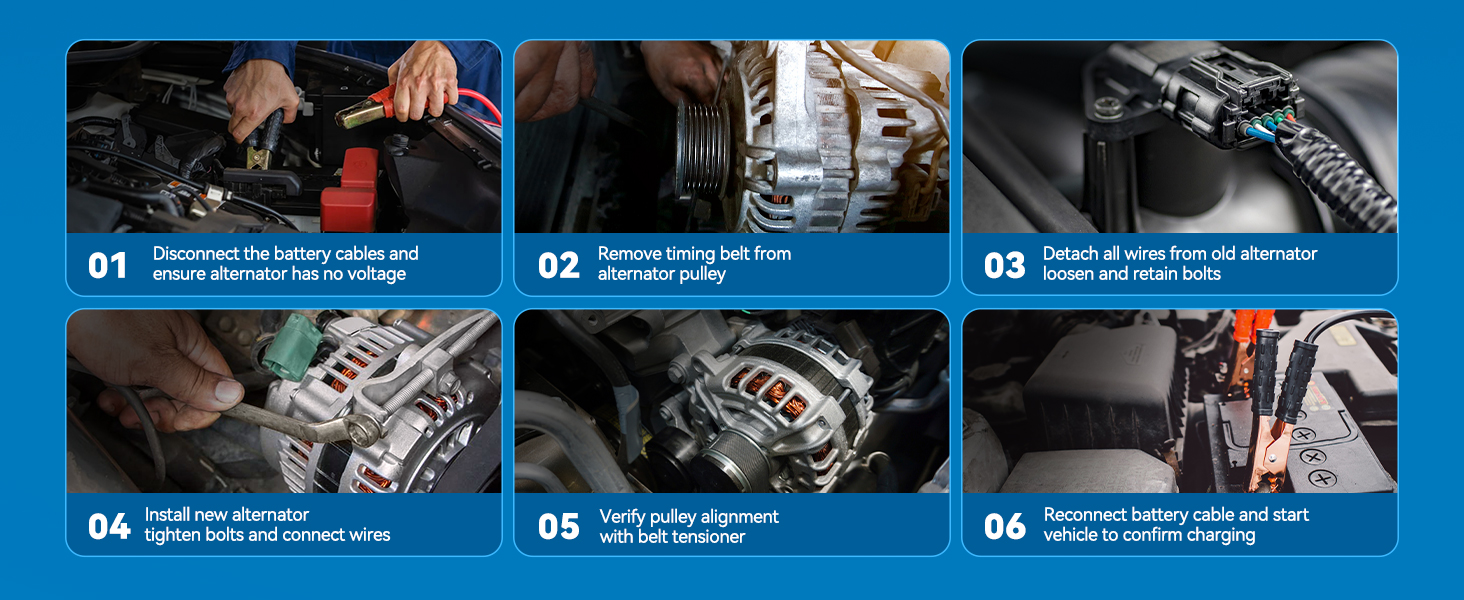

1. Disconnect the Battery Cables and Ensure No Voltage

Begin by disconnecting the negative battery cable to ensure that no voltage runs through the system. This is crucial for safety, as working on the alternator with a live battery can cause electric shock or damage to the vehicle's electrical system. Use a wrench to carefully remove the cable, making sure it doesn't touch any metal parts of the car.

2. Remove the Serpentine Belt from the Alternator Pulley

Locate the serpentine belt and use a belt tensioner tool or wrench to release tension from the belt. Carefully slide the belt off the alternator pulley. Take note of how the belt is routed, or use a diagram to make reinstallation easier. Inspect the belt for any signs of wear or cracks, as it may also need replacement.

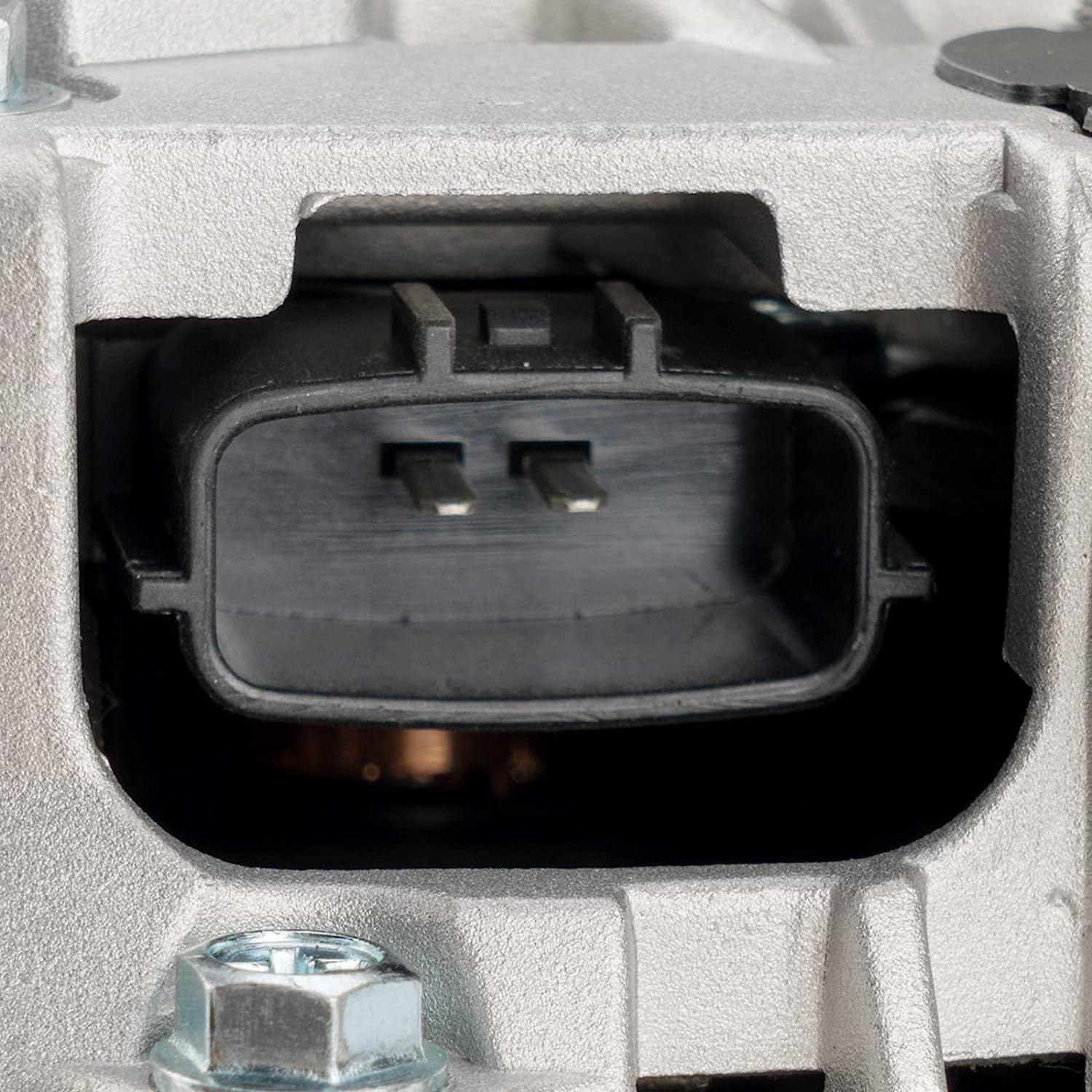

3. Detach All Wires and Loosen Bolts from the Old Alternator

Locate the electrical connections on the back of the alternator. Disconnect all wires, including the positive power cable, ground wire, and any additional connectors. Use appropriate tools to loosen the bolts securing the alternator to the mounting bracket. Keep track of these bolts, as you will need them for installing the new alternator. Make sure all wires are safely tucked away to prevent damage.

4. Install the New Alternator and Secure Bolts

Place the new alternator in the mounting bracket, aligning it with the bolt holes. Insert and hand-tighten the bolts to keep the alternator in position. Once the alternator is properly aligned, use a wrench or ratchet to fully tighten the bolts, ensuring the alternator is securely mounted. Reconnect all wires to the correct terminals, making sure each connection is tight and secure to avoid electrical issues.

5. Verify Pulley Alignment with the Belt Tensioner

Before reinstalling the serpentine belt, make sure the alternator pulley is correctly aligned with the other pulleys in the system. Misalignment can cause the belt to wear out quickly or slip off during operation. Use the belt tensioner tool to create slack and carefully route the serpentine belt back over the alternator pulley and other components, following the original routing pattern.

6. Reconnect the Battery Cable and Test the Alternator

Reconnect the negative battery cable, making sure it is tightly secured. Start the vehicle and observe the dashboard for any warning lights. Use a multimeter to check the alternator's output voltage—it should read between 13.5 and 14.5 volts if the alternator is functioning properly. Listen for any unusual noises, and ensure the belt is running smoothly without slipping or squealing.

About PHILTOP ®

PHILTOP, one of the star brands of SuncentAuto, was built in 2018 by experienced automotive experts, who are into the automotive industry for more than two decades.

The dedicated team ensures that users receive advanced technology products and their overall driving experience is improved with the team's mindful innovations.

Verified Cross Reference Numbers

231000L701, LR1110710C, LR1110710F, 13826N, 231002Y900, 2310031U01, LR1110709, LR1110705, 13826, LR1110705B, 231005Y700, 23100CN100, LR1110709B, 231000L701R, 231009Y500